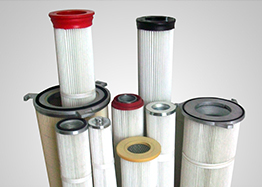

Teflon filters are seen as a solution in areas that require precise filtration. They can be produced as custom manufacturing in the desired size from 5 microns to 30 microns. The use of Teflon filters increases the efficiency of the machines. These filters are also known as anti-static filters.

Where are the Teflon Filters used?

These filters are frequently used in

- Sandblasting industry

- Paint booths

- Jet pulse- dust collection systems

- Laser cutting machines

- Concrete plants

- Water and pool systems

- Welding rooms

- Mining sector

- Marble industry

- Stone crushing facilities

- Environmental technologies

- Furniture industry

- Cogeneration plants of the plastics industry

- Thermal power plants

What are the Considerations related to Teflon Filters?

The quality of the produced Teflon filter is determined by the used materials appropriate in filter production and by being produced in real microns. When producing the Teflon filters the material selection should be made according to the place of use. The produced filter should be designed to resist against high pressure. Experience is one of the most important factors in filter production. The filter which was produced by an expert will not only last longer but also it will prevent your machines and equipment from the unexpected hazards. As Interfil Filtre we provide our customers the experience and knowledge we have gained for many years.